APPENDIXES

(Nonmandatory Information)

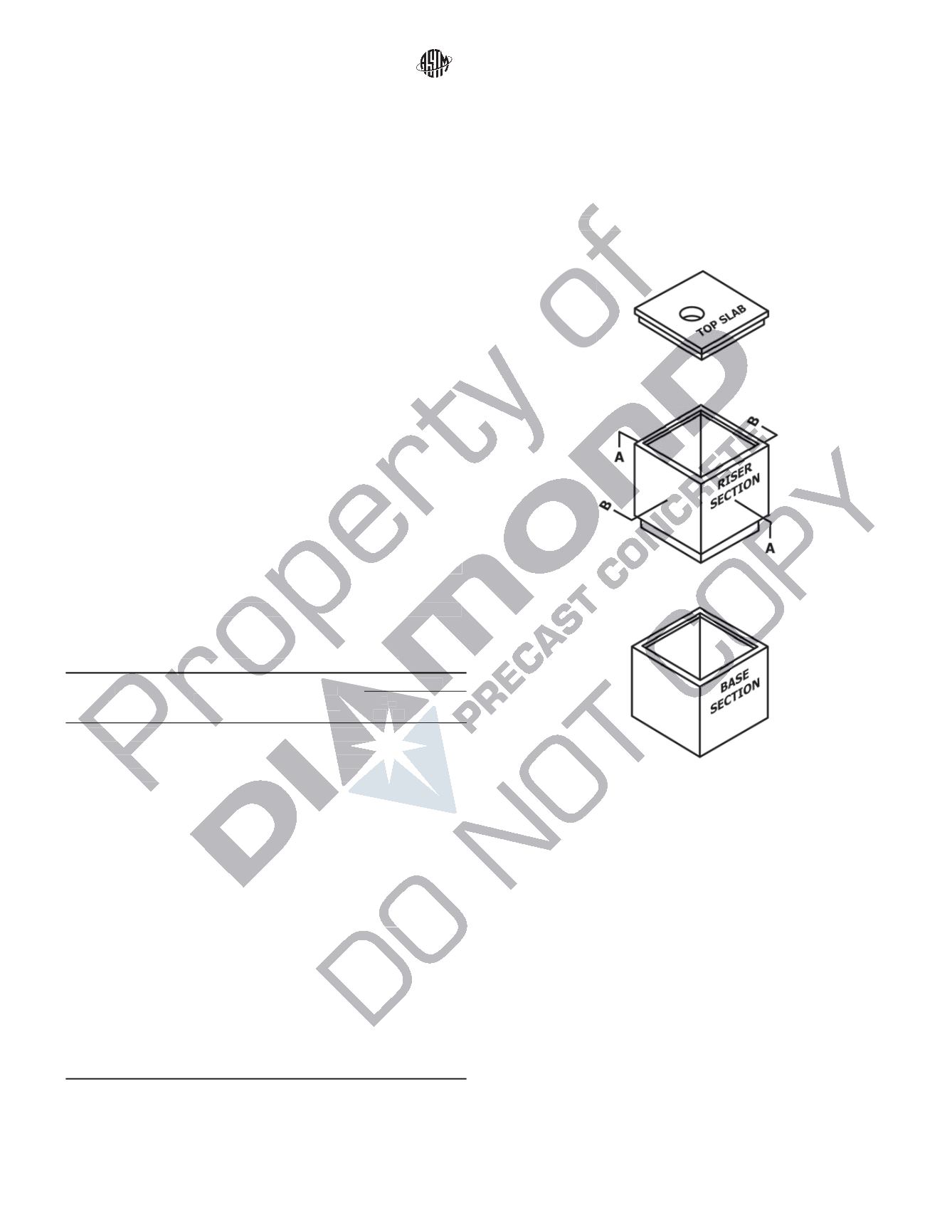

X1. DESIGNS FOR RECTANGULAR BOXES

X1.1 Description of Designs

X1.1.1 The designs in

Table X1.1

are provided as a conve-

nience for specifying, purchasing, and manufacturing. Riser

and base sections are shown in

Fig. X1.1

.

X1.1.2 The successful performance of the product depends

upon the proper selection (based on field conditions), good

manufacturing practices, and proper installation.

X1.1.3 Refer to

Appendix X2

for instructions on the use of

the designs.

X1.2 Structural Analysis

X1.2.1 The analysis is based on the slope-deflection solu-

tion of a frame with nonprismatic members.

X1.2.2 Loads are based on Practice

C890

.

X1.3 Design Calculations

X1.3.1 The concrete shall be designed to be proportioned

for

f

c

' = 4000 psi (28 MPa).

X1.3.2 Reinforcing steel shall be Grade 60 (minimum yield

strength of 60 000 psi) (3.84 MPa).

X1.3.3 The strength design method described in ACI-318 is

used with U.L.F. = 1.7.

X1.3.4 Minimum reinforcement is 0.002 times the gross

concrete area of the cross section.

X1.3.5 Calculations for units with integral slab (top or

bottom) do not take into consideration rigidity or support from

slab.

X1.4 Definitions

X1.4.1

t—

Total thickness of wall (

Fig. X1.2

).

X1.4.2

d—

Distance from centerline of horizontal steel to

inside face of wall (

Fig. X1.2

).

X1.4.3 A

sh

—

Area of horizontal steel per vertical foot (

Fig.

X1.2

).

X1.4.4 A

sv

—

Area of vertical steel per horizontal foot (

Fig.

X1.3

).

X1.4.5

Class—

a term that can be used to describe the

product, for example, 300, 500, 700. The number also refers to

the capacity of the unit in terms of lb/ft

2

(Pa).

TABLE X1.1 Designs for Rectangular Boxes

A

Size

L by W

t (in)

d (in)

Class

w (psf)

Reinforcing

A

sh

(in.

2

/ft)

A

sv

(in.

2

/ft)

2 ft by 2 ft

6

3 300 500 700 0.14 0.14

2 ft 6 in. by 2 ft

6

3 300 500 700 0.14 0.14

2 ft 6 in. by 2 ft 6 in.

6

3 300 500 700 0.14 0.14

3 ft by 2 ft

6

3 300 500 700 0.14 0.14

3 ft by 2 ft 6 in.

6

3 300 500 700 0.14 0.14

3 ft by 3 ft

6

3 300 500 700 0.14 0.14

3 ft 6 in. by 2 ft

6

3 300 500 700 0.14 0.14

3 ft 6 in. by 2 ft 6 in.

6

3 300 500 700 0.14 0.14

3 ft 6 in. by 3 ft

6

3 300 500 700 0.14 0.14

3 ft 6 in. by 3 ft 6 in.

6

3 300 500 700 0.14 0.14

4 ft by 2 ft

6

3 300 500 700 0.14 0.14

4 ft by 2 ft 6 in.

6

3 300 500 700 0.14 0.14

4 ft by 3 ft

6

3 300 500 700 0.14 0.14

4 ft by 3 ft 6 in.

6

3 300 500 700 0.14 0.14

4 ft by 4 ft

6

3 300 500 700 0.14 0.14

4 ft 6 in. by 2 ft 6 in.

6

3 300 500 700 0.14 0.14

4 ft 6 in. by 3 ft

6

3 300 500 700 0.14 0.14

4 ft 6 in. by 3 ft 6 in.

6

3 300 500 700 0.14 0.14

4 ft 6 in. by 4 ft

6

3 300 500 700 0.14 0.14

4 ft 6 in. by 4 ft 6 in.

6

3 300 500 700 0.14 0.14

6 ft by 5 ft 6 in.

6

3 300

0.14 0.14

6 ft by 5 ft 6 in.

6

3

500

0.17 0.14

6 ft by 5 ft 6 in.

6

3

700 0.24 0.14

6 ft by 6 ft

6

3 300

0.14 0.14

6 ft by 6 ft

6

3

500

0.18 0.14

6 ft by 6 ft

6

3

700 0.27 0.14

A

One in. = 25.0 mm.

FIG. X1.1 Typical Assembly

C913 − 08

4

Copyright by ASTM Int'l (all rights reserved); Mon Jun 29 17:07:04 EDT 2015

Downloaded/printed by

Jed Friesen (Predl Systems) pursuant to License Agreement. No further reproductions authorized.